Post-Commission Cleaning

Enhancing Operational Efficiency and Compliance in Process Systems

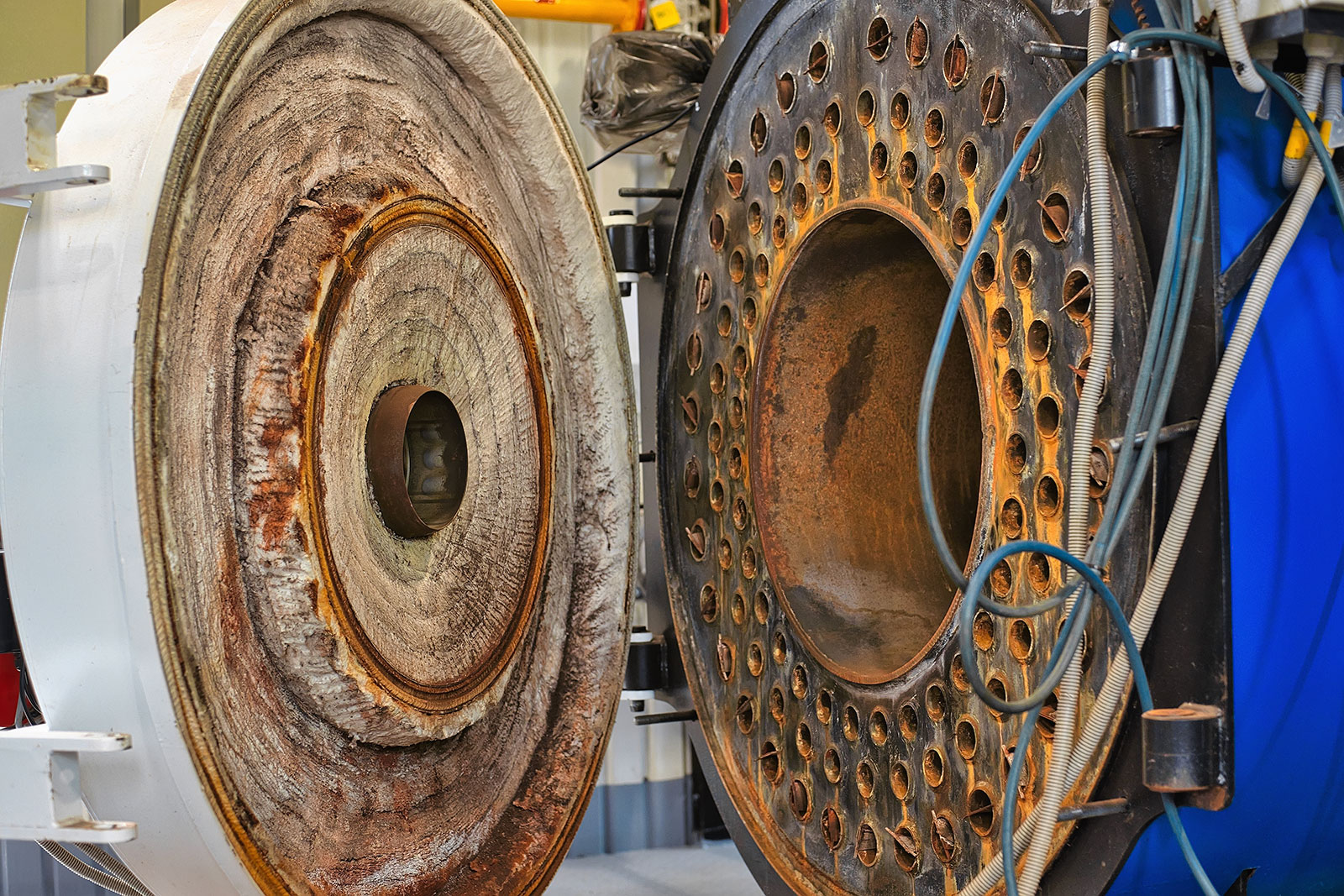

Post-commission cleaning is an essential maintenance service aimed at removing operational contaminants such as fouling, biofilms, scaling, and corrosion by-products from systems that have been in active use. AEKS offers comprehensive post-commission cleaning solutions tailored to industries including pharmaceuticals, biotechnology, food processing, oil&gas, energy and high-purity utilities. This service is particularly relevant during system downtime, shutdowns, or prior to critical inspections and validation procedures.

Why Post-Commission Cleaning is Essential:

During regular operation, process systems are prone to internal contamination from microbial growth, mineral scaling, corrosion by-products, and residual chemicals. Left untreated, these deposits can:

- Compromise product purity and batch quality

- Disrupt fluid dynamics and pressure regulation

- Increase downtime due to fouling-related failures

- Accelerated equipment wear and potential failures

- Lead to non-compliance with industry regulations and safety standards

Regular post-commission cleaning ensures that systems operate at peak efficiency, maintain product integrity, and comply with stringent industry standards.

AEKS's Post-Commission Cleaning Services:

- Customized Chemical Cleaning Protocols: Utilizing industry-approved cleaning agents such as alkaline cleaners, organic acids (e.g., citric, phosphoric), and specialized solvents to effectively remove specific contaminants.

- Advanced Cleaning Techniques: Employing methods like Cleaning-in-Place (CIP) and Cleaning-Out-of-Place (COP) for thorough decontamination of vessels, pipelines, heat exchangers, and other critical equipment.

- High-Purity System Decontamination: Specializing in the cleaning of systems like Purified Water (PW), Water for Injection (WFI), and Clean Steam to eliminate biofilms and organic residues.

- Validation and Compliance Support: Providing comprehensive cleaning validation with swab sampling, rinse analysis, Total Organic Carbon (TOC) testing, and microbial assessments to meet cGMP and industry-specific standards.

Deliverables:

- Detailed documentation adhering to Good Documentation Practices (GDP)

- Customized method statement and risk assessment (RAMS)

- Pre- and post-cleaning inspection reports

- Certificates of cleanliness and compliance

- Photographic evidence and analytical data as required